Enamel Cufflinks

Enamel cufflinks are a high-end type of jewelry that combines traditional craftsmanship with modern fashion. The enamel craft originated in ancient times and has been widely used to decorate the surface of objects. Mainly by applying colored glass powder on the metal surface and heating and melting it, enamel cufflinks present unique colors and textures. Enamel cufflinks not only show exquisite craftsmanship, but also have extremely high durability and corrosion resistance, and can maintain gloss and color for a long time. For consumers who pursue individuality and elegant taste, enamel cufflinks are an attractive choice for men. So there is a good sales market!

Types of Enamel Cufflinks from Our Factory

We produce a wide variety of enamel cufflinks, many of which can be customized according to different countries and groups of people. Please feel free to contact our designers for customized solutions!

Features of Our Cufflinks

Unique color and texture

The enamel craft gives cufflinks a rich color selection and unique surface texture, making it stand out among cufflinks of many materials.

Durability

After high-temperature treatment, the enamel material is firmly combined with the metal surface, has extremely high wear resistance and corrosion resistance, and can remain bright and new even if worn for a long time.

Diverse designs

Due to the flexibility of the enamel craft, enamel cufflinks can express various design concepts through different patterns, colors and shapes to meet the individual needs of different consumers.

Nobleness and artistry

Enamel cufflinks are usually noble and artistic due to their complex production process and unique design. They are especially suitable for wearing in formal occasions to show the wearer’s taste and status.

Occasions for using enamel cufflinks

Like many other types of cufflinks, enamel cufflinks are suitable for various formal and semi-formal occasions. Here Yuheng introduces you to some typical occasions for use:

- Business occasions: In important occasions such as business meetings and formal banquets, wearing a pair of exquisite enamel cufflinks can show the wearer’s taste and status, leaving a deep impression.

- Weddings and celebrations: Enamel cufflinks are also a popular choice in wedding occasions. Many grooms and best men will choose to wear customized enamel cufflinks that match the wedding theme to highlight the sense of ceremony and commemorative significance.

- Social activities: In various high-end social occasions, such as cocktail parties, exhibition openings, etc., enamel cufflinks can add to the wearer’s personal charm and are a fashion highlight in social activities.

- Personalized gifts: Enamel cufflinks are also very suitable as personalized gifts for relatives and friends, especially customized styles, which can better express the gift giver’s intentions and unique taste.

Hot-selling market for enamel cufflinks

As a high-end cufflink, enamel cufflinks occupy an important position in high-end markets around the world. Therefore, the cufflinks we design and produce are very popular in many markets such as Europe, America, Asia, and the Middle East. The following are some major hot-selling markets:

- European market: As one of the birthplaces of luxury goods, Europe has always had a high demand for enamel cufflinks. Especially in fashion-forward countries such as France, Italy, and the United Kingdom, enamel cufflinks are popular.

- Asian market: With the improvement of consumption levels and the enhancement of fashion awareness, the enamel cufflinks market in Asia, especially in China, Japan, and South Korea, is in a rapid growth stage and has become the first choice for many high-end consumers.

- North American market: In the United States and Canada, enamel cufflinks are gradually favored by consumers who pursue individuality and quality. Especially in the business and wedding markets, the demand for enamel cufflinks has steadily increased.

- Middle East market: The Middle East is famous for its luxury. Enamel cufflinks are sought after by local wealthy consumers for their noble appearance and exquisite craftsmanship, and have become the first choice for various high-end occasions.

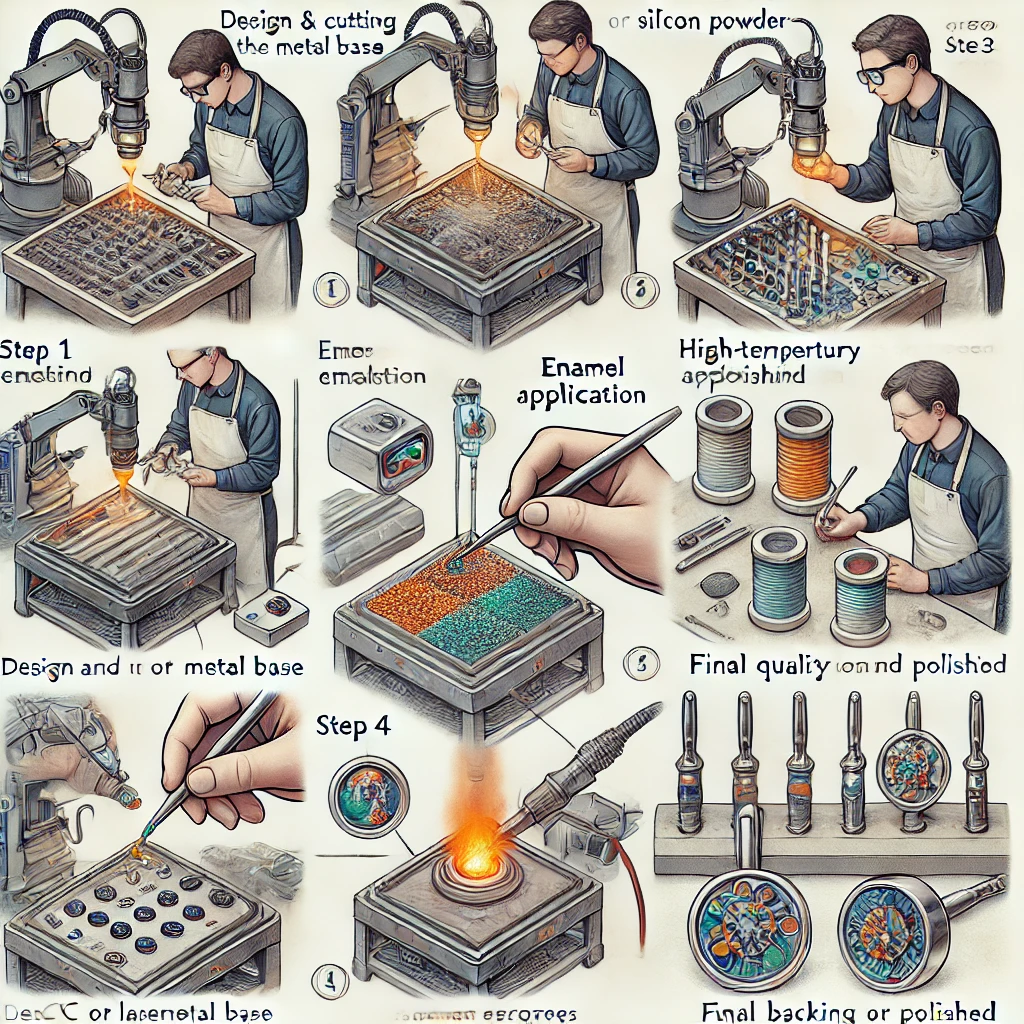

Introduction to the Production Process

The production process of enamel cufflinks is a complex and delicate process that covers multiple steps, each of which requires a high degree of professional skills and rigorous operation to ensure the quality and beauty of the final product. In summary, enamel cufflinks are first made of metal, and then coated with colored silicon enamel, which is heated to 1600 degrees Celsius to complete the production. The following is Yuheng’s detailed description of the production process of enamel cufflinks:

1. Production of metal base

The production of enamel cufflinks starts with the design and processing of the metal base. Usually materials such as brass, stainless steel or silver are used as the base. These metals are not only strong and durable, but also perfectly combined with enamel. At this stage, the designer will perform precise metal cutting and grinding according to the final shape and pattern of the cufflinks to ensure that the surface of the metal base is flat and suitable for coating enamel. This process requires the use of advanced CNC cutting machines or laser cutting technology to ensure the accuracy of size and consistency of shape.

2. Enamel coating

After the metal base is completed, the enamel coating process comes next. Enamel is a material made of fine colored silicon powder. These silicon powders are carefully screened and blended to form different colors and textures, giving enamel cufflinks a rich visual effect. During the coating process, craftsmen use special tools to evenly coat the enamel powder on the metal surface. In order to ensure the saturation and uniformity of the color, multiple coatings are usually performed, and careful inspection is required after each coating to avoid bubbles and unevenness.

3. High-temperature firing

After the coating is completed, the cufflinks will enter the high-temperature firing stage, which is also the core part of the enamel process. In this process, the enamel cufflinks will be placed in a specially designed kiln and heated to about 1600 degrees Celsius. At such a high temperature, the silicon powder in the enamel gradually melts and closely combines with the metal base to form a smooth, hard and shiny surface. The firing time and temperature need to be strictly controlled, because too long firing time or too high temperature will cause the enamel to discolor or crack, while too low temperature may not completely melt the enamel, resulting in an uneven surface.

4. Cooling and polishing

After firing, the enamel cufflinks need to be cooled slowly to prevent cracks caused by sudden temperature changes. After cooling, the surface of the cufflinks is usually hand-polished to further enhance the gloss and surface smoothness. This process not only removes minor defects that may occur during the firing process, but also makes the color of the cufflinks more full and translucent, enhancing the visual effect.

5. Final quality inspection and assembly

After all processing steps are completed, the enamel cufflinks will undergo strict quality inspection to check the color, gloss, surface flatness and structural integrity. Only products that pass the quality inspection will enter the assembly stage to install accessories such as back buckles or chains to ensure wearing comfort and stability. Finally, the finished products will be cleaned and packaged and prepared for shipment.

6. Personalization of enamel cufflinks

For customized enamel cufflinks, every step of the process may vary depending on the customer’s special requirements. The designer may need to make special designs based on the patterns or badges provided by the customer, or even use different colors of enamel powder for gradient effects during the coating process. Every detail is carefully polished to ensure that the customized enamel cufflinks fully meet the customer’s expectations and become a unique work of art.

Enamel cufflinks, with their unique craftsmanship, rich designs and noble temperament, occupy an important position in the global market. For manufacturers, providing high-quality, diversified and customizable enamel cufflinks can not only meet the personalized needs of customers, but also open up a broader market. By deeply understanding the needs and cultural preferences of different markets, manufacturers can better formulate product strategies and further enhance the brand’s influence and market competitiveness.