Cufflinks are more than just a practical accessory to fasten shirt cuffs. For many, they are a symbol of elegance, status, personality, or even heritage. From formal occasions to corporate events, cufflinks play an irreplaceable role in men’s fashion. But behind every beautiful pair of cufflinks is a meticulous manufacturing process that requires precision, artistry, and experience.

With the global demand for high-quality and customizable cufflinks rising steadily, sourcing from a reliable China cufflinks manufacturer has become a popular and smart decision for retailers, corporate buyers, and fashion brands. China offers a compelling mix of competitive pricing, production expertise, and a wide variety of design options.

In this blog, we’ll walk you through everything you need to know about working with a China cufflinks manufacturer, from understanding materials and production techniques to choosing the right partner for your brand. Whether you’re looking to place a bulk order or develop a new line of premium accessories, this guide will be your best starting point.

Why Choose a China Cufflinks Manufacturer?

When it comes to quality accessories like cufflinks, precision and craftsmanship are essential. Over the past two decades, China has developed a strong presence in the accessories and fashion manufacturing sectors, especially in cufflink production. Here’s why working with a China cufflinks manufacturer makes business sense:

1. Cost Efficiency Without Compromising Quality

Manufacturing costs in China are generally lower than in Europe or North America, thanks to advanced production infrastructure and streamlined labor systems. This allows buyers to get premium-quality products at more competitive prices, improving profit margins.

2. Advanced Manufacturing Capabilities

Many top-tier Chinese manufacturers specialize in die-struck processes, precision engraving, and high-polish finishes. These processes are ideal for creating cufflinks with intricate logos, patterns, or even custom symbols. At Shanghai Yuheng, for instance, the use of brass and detailed die-struck techniques ensures each piece meets exacting standards.

3. Flexibility for Custom Orders

One of the strongest advantages of working with a China cufflinks manufacturer is the ability to handle custom and OEM/ODM orders. Whether you need personalized cufflinks for weddings, promotions, or corporate branding, Chinese factories offer high levels of flexibility and customization.

4. Proven Export Experience

Most established Chinese manufacturers have years of experience working with global clients. They are familiar with international trade logistics, packaging standards, and customs regulations—making the whole purchasing process more efficient.

Key Materials and Surface Finishes for Cufflinks

The choice of materials is crucial to both aesthetics and durability. While various metals can be used in cufflink production, one of the most popular materials used by top manufacturers like Shanghai Yuheng is brass.

Why Brass?

Brass is the preferred material for high-quality cufflinks for a number of reasons:

Malleability: It allows for detailed die-struck engraving.

Durability: Brass provides long-term resistance against corrosion.

Finish Flexibility: It can be plated with different finishes such as gold-tone, silver-tone, or antique styles.

Weight: Brass has a premium hand-feel without being overly heavy.

At Shanghai Yuheng, cufflinks are primarily made using solid brass blanks, which are then formed, plated, polished, and packed according to each client’s specifications.

Popular Surface Finishes:

Gold-plated or silver-plated for a classic and elegant look

Antique brass for vintage or rustic themes

Brushed metal for a more modern, industrial style

Two-tone finishes combining gold and silver aesthetics

Matte or mirror-polished styles depending on the design intent

A reputable China cufflinks manufacturer will allow you to preview samples of each finish before mass production to ensure they align with your brand’s image.

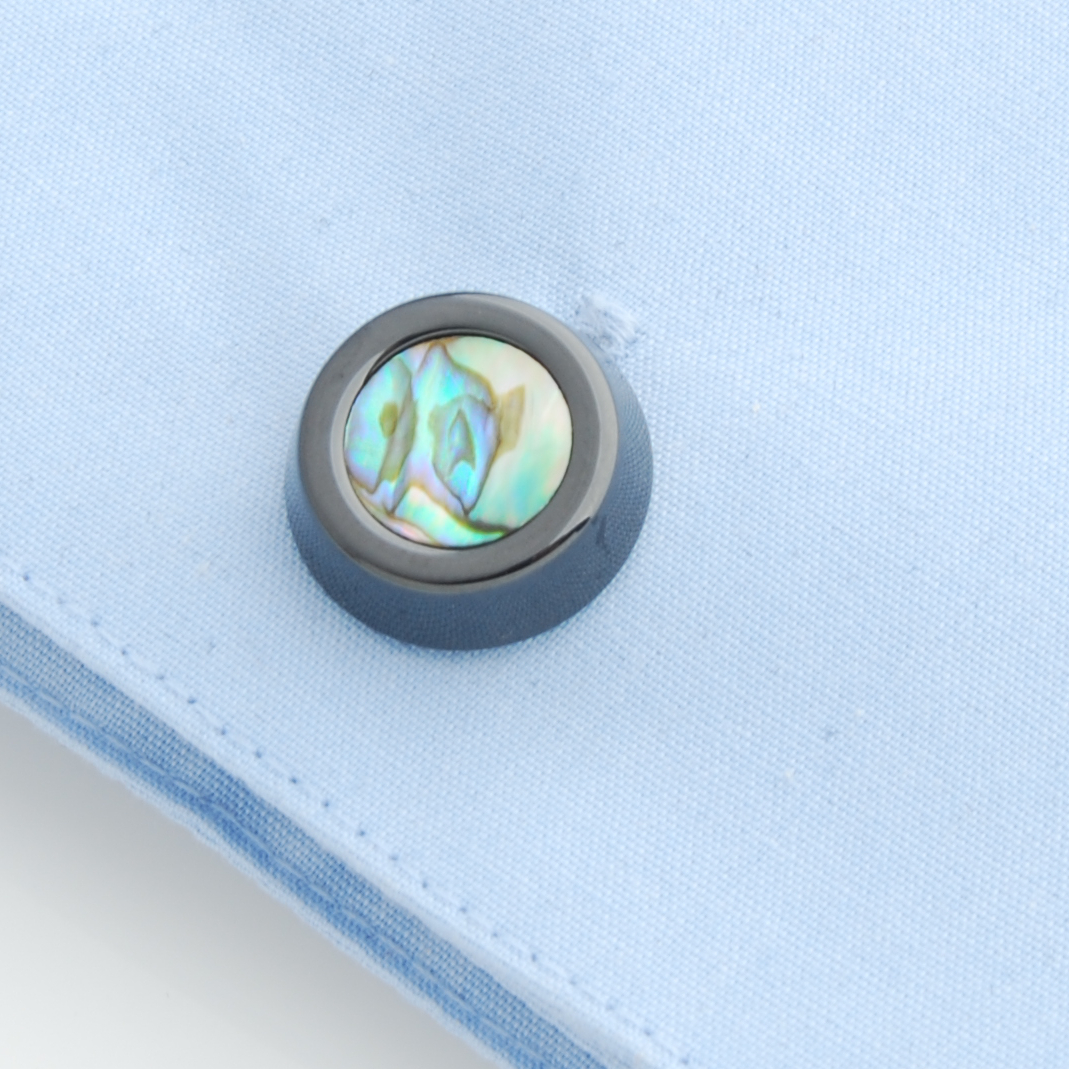

Common Cufflink Styles Offered by Chinese Manufacturers

China-based factories typically offer a wide range of cufflink styles to meet different market preferences. Some of the most commonly produced types include:

Bullet Back Cufflinks: Most popular style with a rotating bar, easy to wear

Whale Back Cufflinks: Similar to bullet back but with a flatter, oval-shaped closure

Fixed Back Cufflinks: More traditional and often used for high-end designs

Chain Link Cufflinks: Elegant and vintage in appearance

Ball Return Cufflinks: Features a rounded ball for a unique back closure

These styles are available in both standard and custom forms, with engravings, stones, enamels, or logos depending on the client’s specifications. A skilled China cufflinks manufacturer like Shanghai Yuheng will help you choose the right style based on your target audience.

How to Select the Right China Cufflinks Manufacturer

Choosing the right partner can make or break your project. Here are the key factors you should consider:

1. Specialization and Experience

Look for a factory that focuses specifically on cufflinks or similar fashion accessories. Shanghai Yuheng, for instance, has over 20 years of experience in the brass cufflinks manufacturing industry. This level of specialization ensures deep expertise in both design and execution.

2. Custom Design Capability

Whether you need a classic oval logo cufflink or a novelty piece shaped like a car or animal, your manufacturer should offer full design support—from sketches to final molds.

3. Sample Production and Quality Control

A reliable China cufflinks manufacturer should be willing to produce samples before full production. This ensures that quality, size, and finish match expectations.

Also, confirm their quality control process. Do they inspect each batch? Are there reports or documentation? How do they manage plating consistency or color matching?

4. Material Transparency

The supplier should openly declare the materials used, especially the metal base. Since Shanghai Yuheng focuses on brass, clients are assured of a robust and lasting core, with better resistance to wear compared to cheaper alloys like zinc.

5. Communication and Language Support

The ability to communicate effectively is often overlooked. A manufacturer that can provide timely updates, clear specifications, and fluent English service can dramatically reduce misunderstandings and delays.

The Customization Process: What to Expect

Once you’ve chosen your China cufflinks manufacturer, the process typically follows a few straightforward steps:

Step 1: Design Submission

You send a design reference (logo, sketch, or mood board). The factory then provides suggestions on dimensions, finish, and structure.

Step 2: Quotation & Confirmation

You’ll receive pricing based on design complexity, quantity, and plating options. After confirmation, a digital render or pre-production sample is created.

Step 3: Sample Approval

A physical sample (often made in brass with your requested finish) is sent for review. Feedback is applied before mass production.

Step 4: Mass Production

Depending on order size, production can take 15–30 days. All pieces are plated, polished, assembled, and packed securely.

Step 5: Final Delivery

Products are shipped via air, sea, or courier, based on your preference. A good China cufflinks manufacturer will offer support through the delivery and post-sale stages as well.

Case Study: Successful Collaboration with Shanghai Yuheng

A European corporate client recently approached Shanghai Yuheng with a need for 5,000 pairs of silver-colored logo cufflinks for a global product launch event. Their original concept included:

A round face with embossed logo

Silver finish

Custom presentation box with velvet lining

Yuheng’s design team worked closely with the client’s marketing team to refine the artwork, propose an ideal size, and match the precise silver plating they desired.

The result?

Samples were approved on the first attempt

Full production was completed within 21 days

Zero plating issues or rejection rate upon delivery

The client reported excellent customer feedback at the event

This is a prime example of what can be achieved when working with an experienced China cufflinks manufacturer who values communication, customization, and precision.

Trends in the Cufflink Industry: What Buyers Should Watch

The cufflink industry has evolved. Today’s buyers—both consumers and businesses—are seeking:

Sustainable production (use of recyclable metals like brass)

Minimalist designs with matte silver or gold finishes

Personalization options for weddings, anniversaries, and branding

Magnetic or slide-in mechanisms for quicker wear

Innovative packaging that enhances perceived value

A forward-thinking China cufflinks manufacturer will always keep up with these trends and offer new options to meet your market’s changing tastes.

Conclusion: The Right China Cufflinks Manufacturer Makes All the Difference

In a competitive market, quality, design, and service matter more than ever. Working with an experienced China cufflinks manufacturer allows you to bring your cufflink concepts to life with confidence and efficiency. From material selection to custom plating, every step should be handled with expertise—and that’s exactly what manufacturers like Shanghai Yuheng provide.

By choosing the right partner, you ensure that each pair of cufflinks tells a story of craftsmanship, elegance, and attention to detail.

If you’re looking for a reliable supplier who specializes in brass cufflinks with silver or gold finishes, who understands your market and provides dedicated support throughout the production process, then your next trusted China cufflinks manufacturer may be closer than you think.